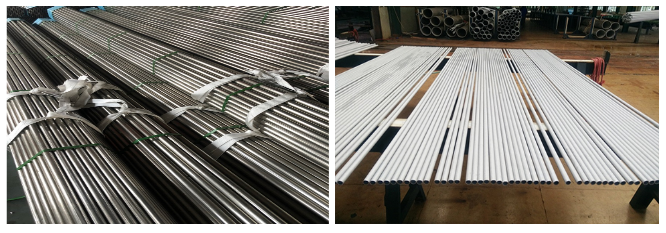

Stainless steel welded tube/pipe

In recent years, the development trend of stainless steel welded tube is relatively good. Both the scale, quality and production technology have made great progress, especially in the field of demand. In addition, with the increasingly mature technology of stainless steel welded tube, stainless stee

PRODUCT INTRODUCTION

In recent years, the development trend of stainless steel welded tube is relatively good. Both the scale, quality and production technology have made great progress, especially in the field of demand. In addition, with the increasingly mature technology of stainless steel welded tube, stainless steel seamless tube can be gradually replaced in many application fields, such as heat exchange equipment, medium and low pressure boiler tube, etc.

Production characteristics of stainless steel welded tube:

light production equipment, less investment, fast construction speed, simple welding method, wide range of product specifications, high dimensional accuracy, small wall thickness deviation, smooth surface and high yield.

Advantages of stainless steel welded tube production:

1 The surface of stainless steel welded pipe is very smooth, not easy to scale, and has anti fouling function. It is not only conducive to heat dissipation, but also does not need to be cleaned frequently, saving time and labor;

2. Uniform wall thickness;

3. The length can be fixed arbitrarily with high precision;

4. Corrosion resistance and long service life.

Stainless steel welded tube shall be used for:

Oil and gas equipment, offshore technology, seawater desalination plant, chemical industry, bridge, storage tank, medical industry, civil engineering, reaction tank, heat exchanger, power plant, petrochemical, shipbuilding, etc

Parameters of stainless steel welded tube:

| Specifications | ASTM A269、ASTM A213、ASTM A312、ASME SA269、ASME SA213、ASME SA312 |

| Material texture | 2205 2507 254smo 310s 316l 904L |

| Type | Welded |

| Processing services | Welding and cutting |

| Tube type | circular |

| Thickness | 0.05mm - 20mm |

| length | ≤ 12000mm or according to customer requirements |

| Outer diameter dimension | Seamless - 1 / 2 "NB to 18" NB weld / ERW - 1 "NB to 16" Nb EFW - 8 "NB to 110" NB |

| Stainless steel welded tube end | Flat end / inclined end |

| Surface | BA/2B/****/NO.3/NO.4/8K/HL/2D/1D |

| Application | Heat exchanger, industry, decoration, medical treatment, etc |

| Colour | custom color |

| Technology | Stainless steel welded tube |

Chemical composition of stainless steel welded tube:

| Grade | UNS No. | EN No. | C | Cr | Ni | Mo | Others |

| 304 | S30400 | 1.4301 | 0.08 | 18.00-20.00 | 8.00 - 12.00 | - | - |

| 304L | S30403 | 1.4307 | 0.035 | 18.00-20.00 | 8.00 - 12.00 | - | - |

| 310S | S31008 | 1.4845 | 0.08 | 24.00 - 26.00 | 19.00 - 22.00 | - | - |

| 316 | S31620 | 1.4401 | 0.08 | 16.00 - 18.00 | 10.00 - 14.00 | 2.00-3.00 | - |

316L | S31603 | 1.4404 | 0.035 | 16.00 - 18.00 | 10.00 - 14.00 | 2.00-3.00 | - |

| 316H | S31603 | - | 0.04-0.10 | 16.00 - 18.00 | 10.00 - 14.00 | 2.00-3.00 | - |

| 316TI | S31635 | 1.4571 | 0.08 | 16.00 - 18.00 | 10.00 - 14.00 | 2.00-3.00 | Ti:5X(C+N) - 0.70 |

| 317L | S31703 | 1.4438 | 0.035 | 16.00 - 20.00 | 11.00 - 15.00 | 3.00-4.00 | - |

| 321 | S32100 | 1.4541 | 0.08 | 17.00 - 19.00 | 9.00-12.00 | - | Ti:5X(C+N) - 0.70 |

| 347H | S34709 | 1.4551 | 0.04-0.10 | 17.00 - 20.00 | 9.00 - 13.00 | - | - |

| 347 | S34700 | 1.4550 | 0.08 | 16.00 - 18.00 | 10.00 - 14.00 | - | - |

| 904L | S8904 | 1.4539 | 0.02 | 19.00 - 23.00 | 23.00 - 28.00 | - | N:0.10 max Cu : 1.0 - 2.0 |